Your all-in-one tool for APQP & New Product Development Management

Most companies are managing their Control Plans & PPAP documents for OEM’s using Excel. That’s not how it should be. We created MESH to simplify all project management like tasks, documents, milestones, approvals, & more all in one system.

How Engineering & NPD leaders benefit from MESH Works

Program Management

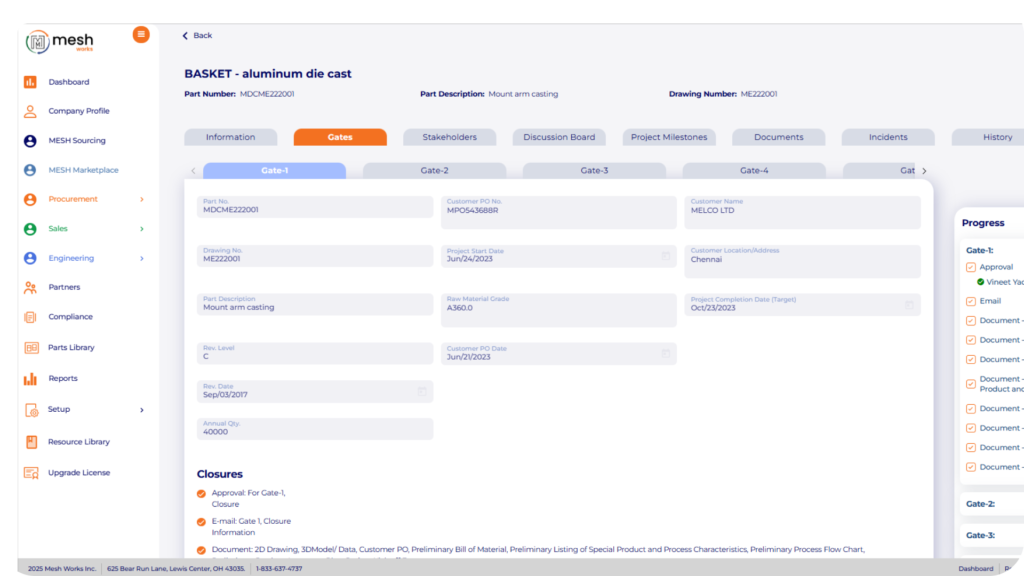

Digital APQP Project Management

Manage all parts of your project in one place – gates, milestones, tasks, documents, communication, approvals, incidents & more.

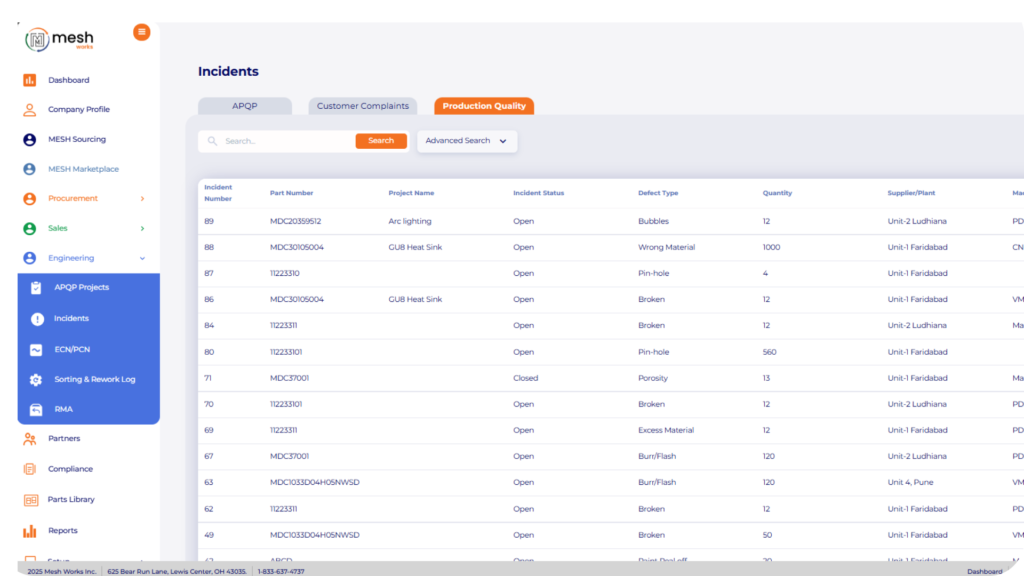

Non-Conformance Management

Mobile Incident Reporting & Digital 8Ds

Manage production quality with easy Incident Reporting and closure with Digital CAPA & 8D formats

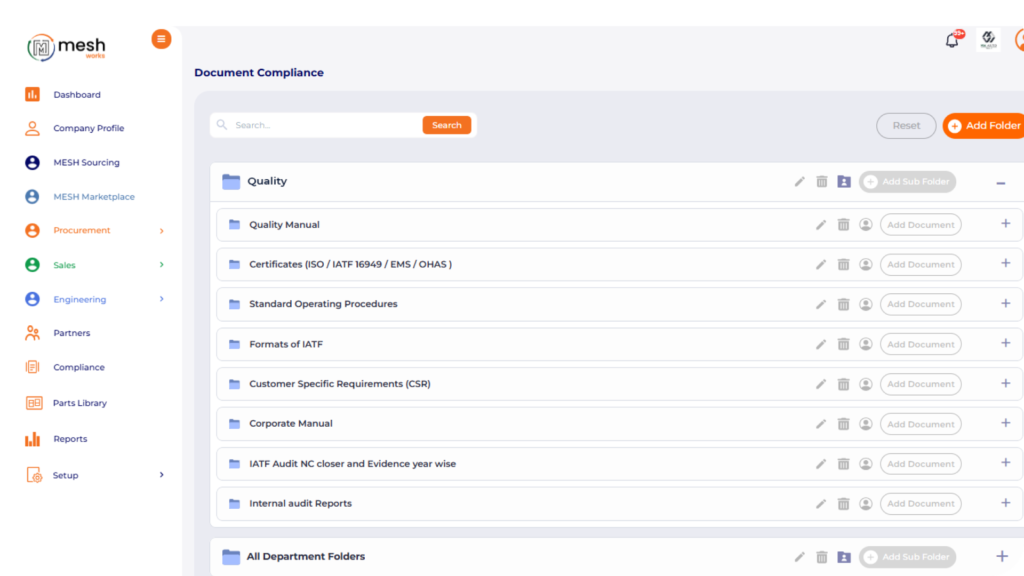

Compliance Tracking

Easily track all documents, compliance & certifications

Suppliers can submit documents within the portal with easy access for the buyer with automated notifications to update certifications as they come close to expiry

Let MESH simplify your APQP Program Management

The QMS Solution

Check out our quick tour of MESH Works QMS to see how it streamlines quality and project management for your operations. You’ll discover APQP project management, digital CAPA workflows, and non-conformance tracking in action.

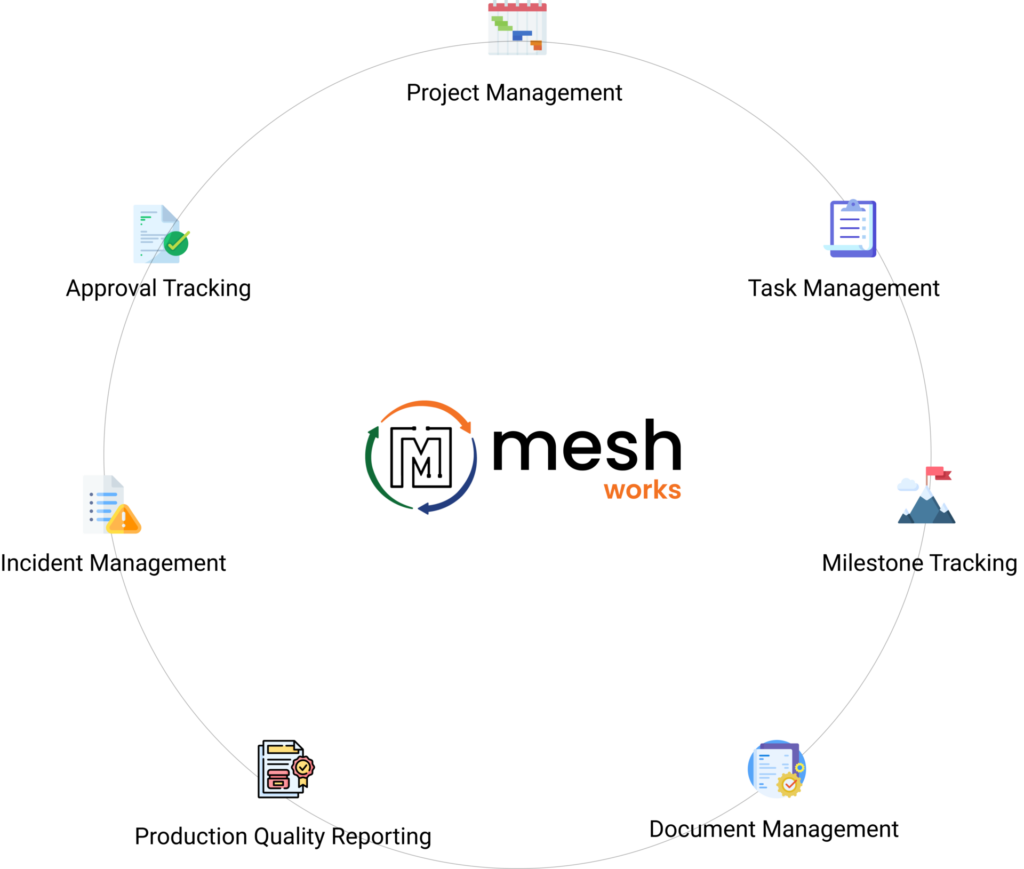

Enhance Efficiency & Quality Management with Our Core Features

Digital APQP

NPD Tracking

PPAP Management

Production Quality Reporting

Incident Tracking

Digital CAPA

Engineering Change Management

Audit Compliance

What can MESH QMS do for you?

APQP

Design engineering and quality teams collaborate on quality/APQP projects throughout the entire process, from launch to design to approval (PPAP) to mass production with MESH. Engineering departments centralize part design and drawings and track any engineering changes. It also ensures project stakeholders submit the necessary documents at each step of the quality process.

Incident Reporting

MESH allows manufacturing organizations to connect their ecosystem to suppliers, factories, vendor partners, 3PLs, and more by allowing them to submit quality incidents on the MESH mobile app through photos, videos, and notes. Identified stakeholders receive a notification ensuring the product development teams see issues on quality projects and react, saving the organization time and money.

Quality Management

MESH QMS allows stakeholders to review quality performance with scorecards and collaborate on any incidents with CAPA, RMA tracking, & more. It also allows ongoing collaboration and development with suppliers to ensure that they are meeting all required standards and specifications.

Did you know that 90% of all FMEA and Control Plan spreadsheets have errors in them according to AIAG? These mistakes not only cost time and money, but also your reputation to deliver.

10 Key Updates in AIAG’s APQP Guidelines (3rd Edition)

Did you know that 90% of all FMEA and Control Plan spreadsheets have errors in them according to AIAG? These mistakes not only cost time and money, but also your reputation to deliver.

Learn how MESH QMS can help.

Simplify Quality Management

A fully implemented quality management system allows teams to control processes and workflows to deliver a quality product.

Connect Stakeholders & Suppliers

Creates efficient communication flows and feedback loops within the organization to ensure correct alignment and ownership.

Compliance with Industry Standards

Allows organizations to ensure delivery of quality-compliant products. QMS is compliant with the AIAG standard.

Document Storage & Revision

Allows teams to find, edit, and collaborate on documents and create guided workflows for drafting, reviewing, approving, and retiring documents.

Quality Reporting to Stakeholders

Teams can report incidents, quality-related issues, & production status while providing visibility to engineering, quality teams, & identified stakeholders.

CAPA & Non-Conformances

Integrate your corrective & preventative actions with your quality management system, including customer complaints, supplier quality defects & incidents.

The QMS Solution

Take a quick tour of MESH QMS to learn all about our APQP, incident reporting, and quality management tools.

Trusted by Industry Leaders

"Driving Efficiency with MESH!"

MESH has streamlined our APQP process, improving efficiency through a digital and systematic approach. Communication is seamless, and finding information is faster than ever, making it an indispensable tool for our team.

MESH helps us streamline our APQP process systematically and digitally, improving team efficiency. Internal and external communication is much smoother, and information can be found with a single click.