At MESH Works, we continually strive to push the boundaries of connecting more buyers to suppliers globally and empower small-midsize manufacturers with digital tools to help develop and improve processes, capabilities, and domain expertise. In this insightful article, learn about the rising demand for suppliers in the EV & Solar Industries and analyze the global situation.

The surge in supplier demand in EV & Solar Industries:

From our conversations with buyers globally over the past year, we have seen a significant increase in the demand for suppliers in the Electric Vehicle and Solar Energy industries.

EVs accounted for 5% of global new car sales in 2020, 9% in 2021, and 14% in 2022, and they are expected to exceed 20% in 2024.

According to the International Energy Agency, United States EV car sales are expected to increase by 20%.

Solar energy has increased at an annual rate of 25% over the past decade and is not slowing down anytime soon.

According to the US Energy Information Administration, the United States’ solar power generation will grow by 75% (163 billion kWh à 286 billion kWh) from 2023 to 2025.

MESH Works’ project with Purdue University Academicians:

MESH partnered with Purdue University’s MBA program to leverage their academic expertise and practical insights to help map the entire end-to-end supply chain from raw materials procurement to finished goods delivery for 1) EVs and 2) Solar Panels. The students helped with market research, process flow mapping, and supplier identification for all components in the supply chain.

The students quickly realized this is more than just finding manufacturing companies – Preet Shah, one of the lead students on the project, stated in a recent interview regarding the project,

“We started off thinking [this project] was just about identifying companies, but quickly realized it was much deeper – finding the right integrators and suppliers to support the end customer truly. This experience taught us that it’s not just about solving a problem but understanding the industry’s nuances and connecting the right dots to deliver real value.”

By the end of the project, the Purdue team delivered a complete supply chain process mapping for the EV industry and identified the Integrators (OEMs) and Tier 1 suppliers globally. They also offered the same study on Solar to identify the main subassemblies and critical suppliers for those modules/units. Next, we explore some of the key highlights of the overall project.

Key Highlights:

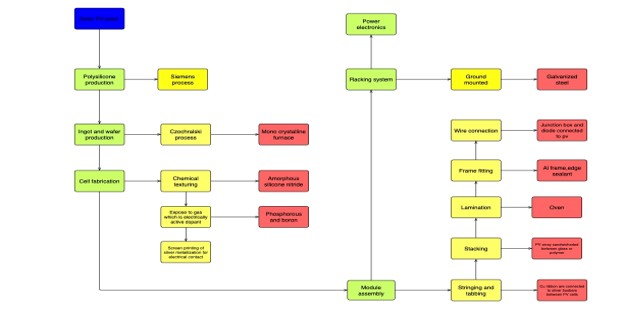

80% of suppliers identified as Tier 2 Solar suppliers based in China

The main parts of the Solar panel manufacturing process are Polysilicon production, Ingot & wafer production, Cell fabrication, Module assembly, Rack system, and Power electronics.

Most EV suppliers are in China, Europe, or the USA (These three regions represent 95% of global EV car sales).

Most EV suppliers are in China, Europe, or the USA (These three regions represent 95% of global EV car sales).

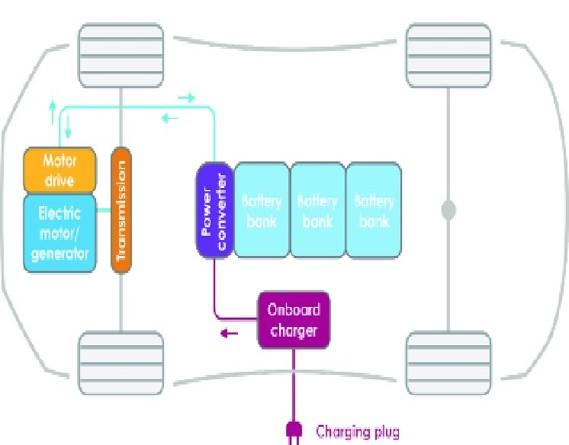

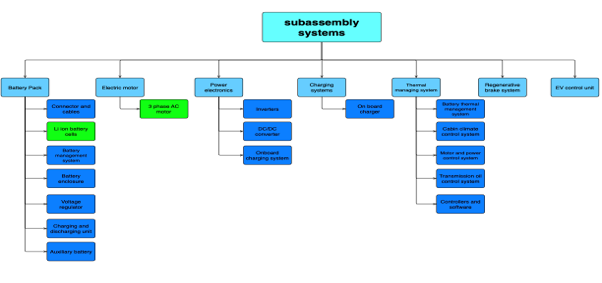

The main sub-assemblies for EVs include the Battery Pack, Electric Motor, Power Electronics, Charging System, Thermal Management System, Regenerative Brake System, and EV Control Unit.

We are excited to announce that two more detailed blogs will follow, diving deeper into specific aspects of the two industries’ supply chains covered: EV and Solar Energy. Stay tuned for the upcoming blogs, which will have insights into the EV and solar supply chains, where we will explore components, sub-assemblies, and industry-specific details.

We are excited to announce that two more detailed blogs will follow, diving deeper into specific aspects of the two industries’ supply chains covered: EV and Solar Energy. Stay tuned for the upcoming blogs, which will have insights into the EV and solar supply chains, where we will explore components, sub-assemblies, and industry-specific details.